Support In Performance offers consultancy services to equipment manufacturers, municipal wastewater plant operators and industrial clients. We have over 30 years of experience in separation and filtration technologies for wastewater treatment and industrial processes including service and maintenance, training, commissioning, optimization and project management.

Support In Performance offers consultancy services to equipment manufacturers, municipal wastewater plant operators and industrial clients. We have over 30 years of experience in separation and filtration technologies for wastewater treatment and industrial processes including service and maintenance, training, commissioning, optimization and project management.

Support In Performance is specialized in designing and managing projects related to:

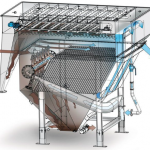

- Sludge and bio-solids treatment systems including thickening and dewatering equipment

- Industrial separation and filtration applications

- Waste to energy (WtE) projects

- Industrial wastewater treatment systems (pre-treatment and biological treatment)

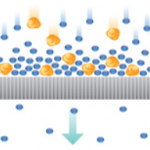

Solid–liquid separation plays a key role in nearly all manufacturing industries, including chemical, mineral, paper, electronics, food, beverage, pharmaceutical, and biochemical industries, as well as in energy production, pollution abatement, and environmental control. It also serves to fulfill vital needs of our daily life, since we must have cartridge oil/fuel filters for operating an automobile, a paper filter for the coffee machine, a sand filter bed for the municipal water treatment plant, and so on. In fact, modern society cannot function properly without the benefit of the solid-liquid separation. Technically, solid–liquid separation involves the removal and collection of a discrete phase of matter(particles) existing in a dispersed or colloidal state in suspension. This separation is most often performed in the presence of a complex medium structure in which physical, physicochemical and/or electrokinetic forces interact. Their analysis requires combined knowledge of fluid mechanics, particle dynamics, solution chemistry, and surface/interface sciences. Although the industrial equipment classified as solid–liquid separation devices are too numerous to be cited individually, it is generally accepted that these may be grouped into six categories of unit operations:

- screening

- sedimentation

- centrifugation

- hydrocycloning

- flotation

- filtration